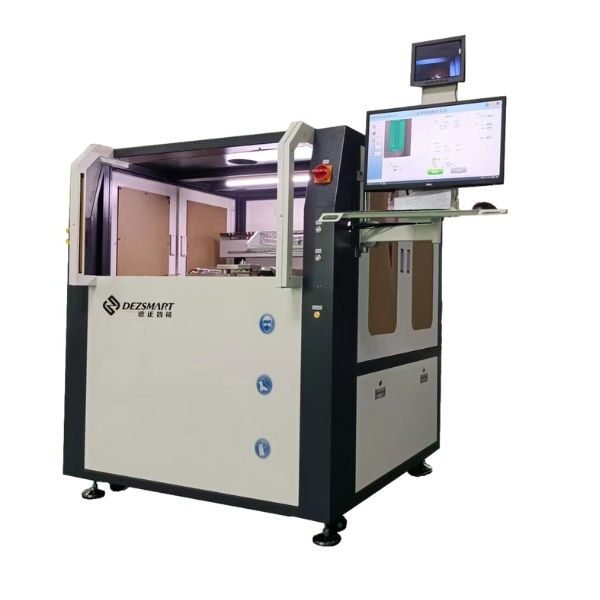

H3900L Selective Wave Soldering Machine

The H3900L selective wave soldering typically consists of three modules: flux spraying, preheating, and soldering. Through the equipment’s programming device, the flux spraying module can selectively spray flux for each solder point on the board in sequence. After being preheated by the preheating module, the soldering module completes the soldering of each solder point one by one.

- Integrated full-functionality machine, with three PCB boards or three fixtures simultaneously working in the spray, preheat, and soldering processes within the machine.

- Independent spray motion platform and independent soldering motion platform.

- High soldering quality, significantly improving the direct pass rate of soldering.

- SMEMA online transportation, supporting customers for flexible line assembly.

- Fully computer-controlled, parameters are set and saved on the computer. Configuration files are generated for easy traceability and storage.

- Software developed based on WINDOWS, with user-friendly and traceable operation.

- Direct use of PCB images for path programming, with settings available for path start point, soldering movement speed, Z-axis height, wave peak height, etc.

- Real-time display of the soldering process. The soldering process can be monitored through the camera feed to the display screen.

- Complete software monitoring of key parameters, such as temperature, speed, pressure, etc.

- Upgradable to automatic wave height correction function. It is possible to set how often to correct the wave height after a certain number of boards.

- Independently designed all-aluminum cast motion platform, with lightweight design that improves running speed while ensuring the rigidity of the platform.

1.What type of PCB boards are suitable for your selective wave soldering machine?

A:Our selective wave soldering machine is especially suitable for high-density PCB boards with complex components (such as BGA, QFN, etc.), multi-layer, double-sided assembly. It can precisely control the soldering area to avoid waste and soldering errors.

2.Is your equipment maintenance and cleaning complicated?

A:Our equipment needs regular cleaning and maintenance, especially the crest part, to ensure its stability and long-term performance. With correct operation and regular maintenance, the service life of the equipment can be extended.

3.How is the soldering accuracy of your equipment?

A:Our selective wave soldering machine can provide high-precision soldering under the conditions of setting parameters on the PC side, especially when dealing with small components and high-density circuit boards, which can ensure the quality and consistency of solder joints.

4.How efficient are your equipment?

A:Our selective wave soldering machines are highly efficient and suitable for small batch and high mix production environments, but the soldering speed and efficiency will be affected by the complexity of the PCB board and the size of the soldering area.

5. How long is the warranty for your equipment? How is the after-sales service?

A: We provide a 1-2 year warranty (depending on the model) and lifetime technical support. Our after-sales service includes:

✅ Remote technical support (telephone/video guidance)

✅On-site maintenance (door-to-door service available)

✅Spare parts supply (equipment wearing parts can be provided for a long time).

Featured Specs

| Model | DEZ-H3900L |

|---|---|

| Machine Dimensions | L3150 x W1680 x H1690mm |

| Total Power | 20KW |

| Power Supply | Three-phase, five-wire, 380V |

| Power Line Requirement | 2.5² Copper Wire |

| Air Source Requirement | 3-5kg/cm² |

| Nitrogen Source Requirement | Purity: 99.999% |

| Control System | Industrial PC + Controller PLC |

| Soldering Area | L500 X W450MM |

| PCB Transport Direction | Left to Right Horizontal Transport |

| Motion Axes | X, Y |

| Motion Control | Closed-loop Servo Control |

| Positioning Accuracy | ± 0.05 mm |

| Frame Type | Steel Welded |

| Flux Capacity | 1L |

| Preheating Method | Bottom Infrared Preheating, Top Hot Air Preheating |

| Preheating Power | 6KW |

| Melting Time | 45 Minutes (with programmable pre-heating) |

| Maximum Soldering Pot Temperature | 350 °C |

| Soldering Pot Power | 1.2KW |