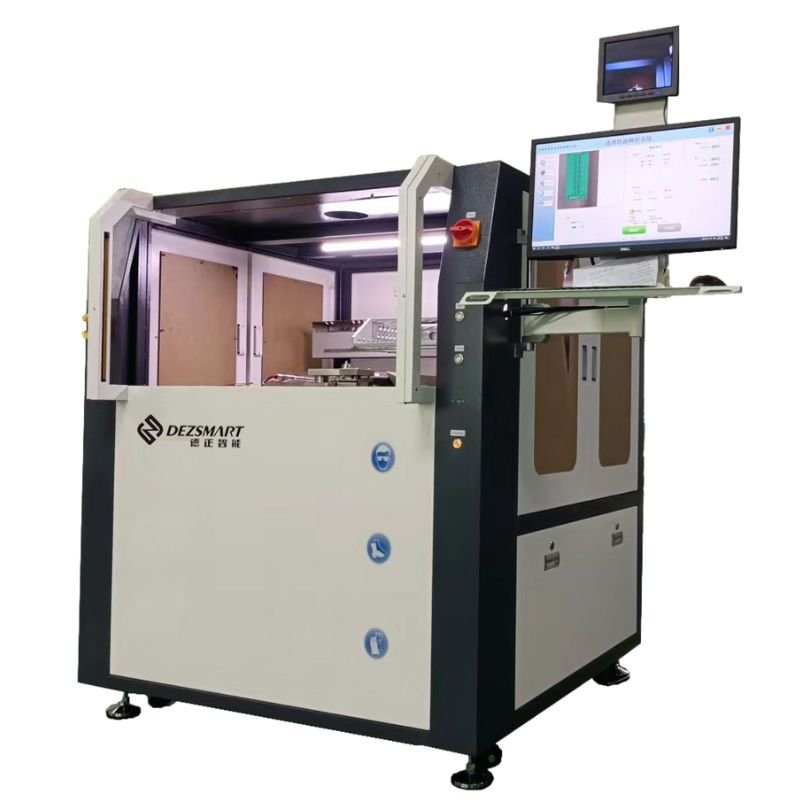

H3630 Selective Wave Soldering Machine

The H3630 Selective wave soldering machine typically consists of three modules: flux application, preheating, and soldering. application range: military electronics, aerospace ship electronics, automotive electronics, digital cameras, printers and other welding requirements of high, complex multi-layer PCB through hole welding process.

- Our machine boasts a unique body structure, ensuring stable performance and the highest cleaning efficiency in the industry.

- Specifically designed for removing solder balls, flux residues, and solder mask marks.

- Utilizes imported bristle brushes with antistatic properties to prevent electrostatic discharge and protect PCBA boards.

- Suitable for PCB boards with edges (minimum edge distance of 1.5mm) and adaptable to a wide range of PCBA board widths.

- Thickened spring clips ensure that PCBA boards remain in place during transport.

- Automatic detergent coating system ensures even distribution of wash water on PCBA board soldering surfaces without affecting other components’ surfaces.

- Combination of rotary brushes and dual rollers ensures thorough cleaning from all directions with no dead spots.

- Height and speed of cleaning brushes are adjustable (stepless speed regulation) to meet different cleaning requirements.

- Waste generated during operation is automatically collected in the bottom filter box for easy disposal.

- Equipped with high-quality electronic variable-speed motors for durability and longevity.

- Operates on 220 volts for convenient use.

- Features branded electrical components and control systems to ensure reliability and stability.

- Utilizes modular control for easy maintenance and troubleshooting.

1.What type of PCB boards are suitable for your selective wave soldering machine?

A:Our selective wave soldering machine is especially suitable for high-density PCB boards with complex components (such as BGA, QFN, etc.), multi-layer, double-sided assembly. It can precisely control the soldering area to avoid waste and soldering errors.

2.Is your equipment maintenance and cleaning complicated?

A:Our equipment needs regular cleaning and maintenance, especially the crest part, to ensure its stability and long-term performance. With correct operation and regular maintenance, the service life of the equipment can be extended.

3.How is the soldering accuracy of your equipment?

A:Our selective wave soldering machine can provide high-precision soldering under the conditions of setting parameters on the PC side, especially when dealing with small components and high-density circuit boards, which can ensure the quality and consistency of solder joints.

4.How efficient are your equipment?

A:Our selective wave soldering machines are highly efficient and suitable for small batch and high mix production environments, but the soldering speed and efficiency will be affected by the complexity of the PCB board and the size of the soldering area.

5. How long is the warranty for your equipment? How is the after-sales service?

A: We provide a 1-2 year warranty (depending on the model) and lifetime technical support. Our after-sales service includes:

✅ Remote technical support (telephone/video guidance)

✅On-site maintenance (door-to-door service available)

✅Spare parts supply (equipment wearing parts can be provided for a long time).

Featured Specs

| Model | DEZ-H3630 |

|---|---|

| Machine Dimensions | L1150mm X W1260mm X H850mm (excluding base) |

| Total Power Consumption | 5KW |

| Power Supply | Single phase 220V 50HZ |

| Power Cable Requirement | 2.5mm² copper wire |

| Air Source Requirement | 3-5kg/cm² |

| Nitrogen Source Requirement | Nitrogen purity requirement: 99.999% |

| Control System | Industrial PC |

| Soldering Area | 300X300MM |

| PCB Placement Method | Manual placement |

| Motion Axes | X, Y, Z |

| Motion Control | Panasonic closed-loop servo control |

| Positioning Accuracy | ± 0.05 mm |

| Frame Type | Steel base frame welding |

| Flux Capacity | 2L |

| Preheating Method | Halogen lamp |

| Preheating Power | 5KW |

| Melting Time | 45 Minutes (with programmable pre-heating) |

| Maximum Solder Pot Temperature | 350 °C |

| Solder Pot Power | 1.2KW |