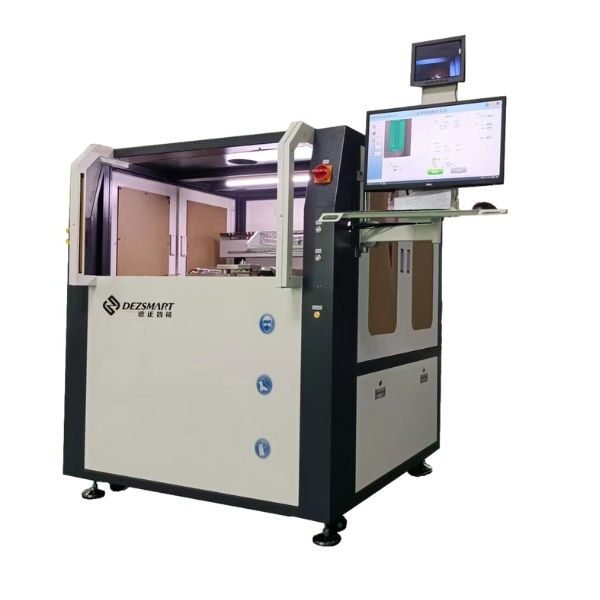

H3600A Selective Wave Soldering Machine

The H3600A transfers the molten solder to the welding point through the wave crest method. It is suitable for small batches and multiple varieties of products. The equipment has a high level of automation and can achieve precise welding.

- Fully functional offline model in a compact space.

- PCB board moves, spray and welding platform are fixed

- High welding quality

- It can be placed beside the production line for welding work, and the line assembly is quite flexible.

- Fully computer controlled, all parameters are set and saved on the computer. Generate configuration files for easy traceability and storage, like moving path, solder temperature, flux type, solder type ,n2 temperature etc, best trace-ability and easy to get repeat soldering quality.

1.What type of PCB boards are suitable for your selective wave soldering machine?

A:Our selective wave soldering machine is especially suitable for high-density PCB boards with complex components (such as BGA, QFN, etc.), multi-layer, double-sided assembly. It can precisely control the soldering area to avoid waste and soldering errors.

2.Is your equipment maintenance and cleaning complicated?

A:Our equipment needs regular cleaning and maintenance, especially the crest part, to ensure its stability and long-term performance. With correct operation and regular maintenance, the service life of the equipment can be extended.

3.How is the soldering accuracy of your equipment?

A:Our selective wave soldering machine can provide high-precision soldering under the conditions of setting parameters on the PC side, especially when dealing with small components and high-density circuit boards, which can ensure the quality and consistency of solder joints.

4.How efficient are your equipment?

A:Our selective wave soldering machines are highly efficient and suitable for small batch and high mix production environments, but the soldering speed and efficiency will be affected by the complexity of the PCB board and the size of the soldering area.

5. How long is the warranty for your equipment? How is the after-sales service?

A: We provide a 1-2 year warranty (depending on the model) and lifetime technical support. Our after-sales service includes:

✅ Remote technical support (telephone/video guidance)

✅On-site maintenance (door-to-door service available)

✅Spare parts supply (equipment wearing parts can be provided for a long time).

Specifiche in evidenza

| Modello | DEZ-H3600A |

|---|---|

| Dimensioni della macchina (esclusa la base) | L1150mm X L1260mm X H850mm |

| Consumo totale di energia | 5KW |

| Alimentazione elettrica | Monofase 220V 50HZ |

| Requisiti del cavo di alimentazione | Filo di rame da 2,5 mm² |

| Requisiti della fonte d'aria | 3-5 kg/cm² |

| Requisito della fonte di azoto | Purezza: 99,999% |

| Sistema di controllo | PC industriale |

| Area di saldatura | L400 * W300 MM |

| Metodo di posizionamento della scheda | Posizionamento manuale della scheda |

| Assi di movimento | X, Y, Z |

| Controllo del movimento | Servocontrollo ad anello chiuso Panasonic |

| Precisione di posizionamento | ± 0,05 mm |

| Tipo di telaio | Saldatura del telaio di base in acciaio |

| Capacità di flusso | 2L |

| Metodo di preriscaldamento | Lampade alogene |

| Potenza di preriscaldamento | 5KW |

| Tempo di fusione | 45 minuti (con preriscaldamento programmabile) |

| Temperatura massima del piatto di saldatura | 350 °C |

| Potenza del crogiolo di saldatura | 1,2KW |