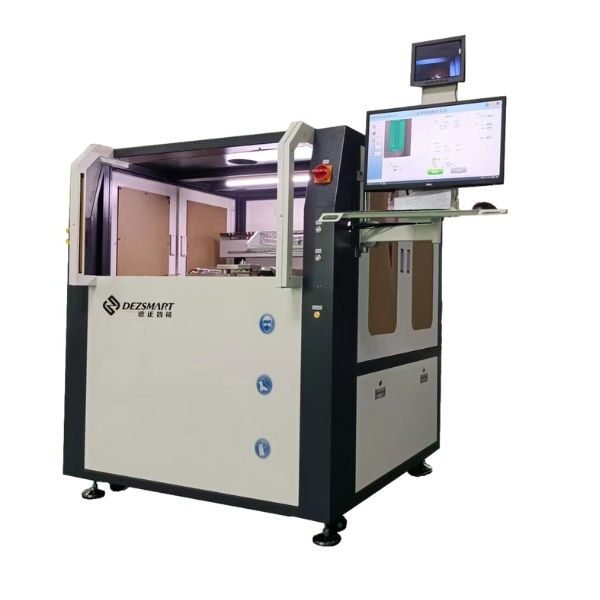

Machine à souder à la vague sélective H3900L

The H3900L selective wave soldering typically consists of three modules: flux spraying, preheating, and soldering. Through the equipment’s programming device, the flux spraying module can selectively spray flux for each solder point on the board in sequence. After being preheated by the preheating module, the soldering module completes the soldering of each solder point one by one.

- Machine intégrée à fonctionnalité complète, avec trois cartes de circuits imprimés ou trois montages fonctionnant simultanément dans les processus de pulvérisation, de préchauffage et de brasage au sein de la machine.

- Plate-forme de mouvement indépendante pour la pulvérisation et plate-forme de mouvement indépendante pour la soudure.

- Qualité de brasage élevée, amélioration significative du taux de passage direct de la soudure.

- Transport en ligne SMEMA, pour aider les clients à assembler des lignes flexibles.

- Entièrement contrôlés par ordinateur, les paramètres sont réglés et sauvegardés sur l'ordinateur. Des fichiers de configuration sont générés pour faciliter la traçabilité et le stockage.

- Logiciel développé sur la base de WINDOWS, avec un fonctionnement convivial et traçable.

- Utilisation directe des images de circuits imprimés pour la programmation des trajectoires, avec des paramètres disponibles pour le point de départ de la trajectoire, la vitesse du mouvement de brasage, la hauteur de l'axe Z, la hauteur du pic de l'onde, etc.

- Affichage en temps réel du processus de brasage. Le processus de brasage peut être surveillé par l'intermédiaire de la caméra qui alimente l'écran d'affichage.

- Surveillance logicielle complète des paramètres clés, tels que la température, la vitesse, la pression, etc.

- Possibilité de mettre à jour la fonction de correction automatique de la hauteur des vagues. Il est possible de définir la fréquence de correction de la hauteur des vagues après un certain nombre de planches.

- Plate-forme de mouvement entièrement en aluminium moulé, conçue de manière indépendante, avec un design léger qui améliore la vitesse de marche tout en garantissant la rigidité de la plate-forme.

1.What type of PCB boards are suitable for your selective wave soldering machine?

A:Our selective wave soldering machine is especially suitable for high-density PCB boards with complex components (such as BGA, QFN, etc.), multi-layer, double-sided assembly. It can precisely control the soldering area to avoid waste and soldering errors.

2.Is your equipment maintenance and cleaning complicated?

A:Our equipment needs regular cleaning and maintenance, especially the crest part, to ensure its stability and long-term performance. With correct operation and regular maintenance, the service life of the equipment can be extended.

3.How is the soldering accuracy of your equipment?

A:Our selective wave soldering machine can provide high-precision soldering under the conditions of setting parameters on the PC side, especially when dealing with small components and high-density circuit boards, which can ensure the quality and consistency of solder joints.

4.How efficient are your equipment?

A:Our selective wave soldering machines are highly efficient and suitable for small batch and high mix production environments, but the soldering speed and efficiency will be affected by the complexity of the PCB board and the size of the soldering area.

5. How long is the warranty for your equipment? How is the after-sales service?

A: We provide a 1-2 year warranty (depending on the model) and lifetime technical support. Our after-sales service includes:

✅ Remote technical support (telephone/video guidance)

✅On-site maintenance (door-to-door service available)

✅Spare parts supply (equipment wearing parts can be provided for a long time).

Specs en vedette

| Modèle | DEZ-H3900L |

|---|---|

| Dimensions de la machine | L3150 x L1680 x H1690mm |

| Pouvoir total | 20KW |

| Source de courant | Triphasé, cinq fils, 380V |

| Exigences en matière de lignes électriques | 2.5² Fil de cuivre |

| Exigences relatives à la source d'air | 3-5kg/cm² |

| Exigence relative à la source d'azote | Pureté : 99,999% |

| Système de contrôle | PC industriel + contrôleur PLC |

| Zone de soudure | L500 X L450MM |

| Direction du transport du PCB | Transport horizontal de gauche à droite |

| Axes de mouvement | X, Y |

| Contrôle du mouvement | Servocommande en boucle fermée |

| Précision du positionnement | ± 0,05 mm |

| Type de cadre | Acier soudé |

| Capacité de flux | 1L |

| Méthode de préchauffage | Préchauffage infrarouge par le bas, préchauffage à l'air chaud par le haut |

| Puissance de préchauffage | 6KW |

| Temps de fusion | 45 minutes (avec préchauffage programmé) |

| Température maximale du pot de soudure | 350 °C |

| Pot de soudure Puissance | 1,2KW |