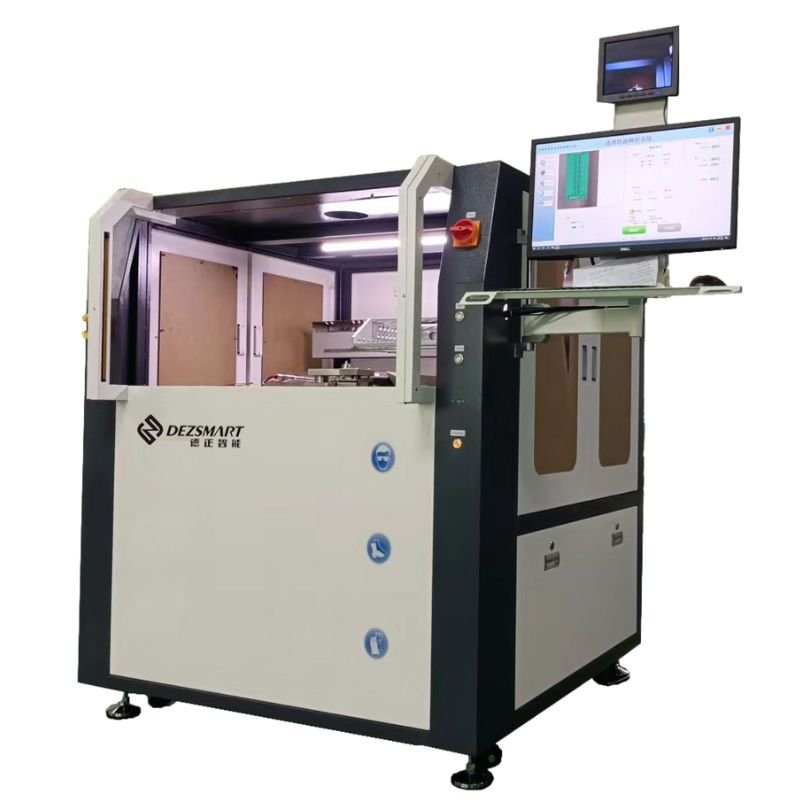

H3630 Máquina de soldadura por ola selectiva

The H3630 Selective wave soldering machine typically consists of three modules: flux application, preheating, and soldering. application range: military electronics, aerospace ship electronics, automotive electronics, digital cameras, printers and other welding requirements of high, complex multi-layer PCB through hole welding process.

- Nuestra máquina cuenta con una estructura de carrocería única, que garantiza un rendimiento estable y la mayor eficacia de limpieza del sector.

- Específicamente diseñado para eliminar bolas de soldadura, residuos de fundente y marcas de máscara de soldadura.

- Utiliza cepillos de cerdas importados con propiedades antiestáticas para evitar descargas electrostáticas y proteger las placas PCBA.

- Adecuado para placas de circuito impreso con bordes (distancia mínima entre bordes de 1,5 mm) y adaptable a una amplia gama de anchuras de placas de circuito impreso.

- Los clips de resorte engrosados garantizan que las placas PCBA permanezcan en su sitio durante el transporte.

- El sistema automático de recubrimiento con detergente garantiza una distribución uniforme del agua de lavado en las superficies de soldadura de la placa PCBA sin afectar a las superficies de otros componentes.

- La combinación de cepillos giratorios y rodillos dobles garantiza una limpieza a fondo desde todas las direcciones sin puntos muertos.

- La altura y la velocidad de los cepillos de limpieza son ajustables (regulación continua de la velocidad) para satisfacer diferentes requisitos de limpieza.

- Los residuos generados durante el funcionamiento se recogen automáticamente en la caja inferior del filtro para facilitar su eliminación.

- Equipadas con motores electrónicos de velocidad variable de alta calidad para una mayor durabilidad y longevidad.

- Funciona con 220 voltios para un uso más cómodo.

- Incorpora componentes eléctricos y sistemas de control de marca para garantizar la fiabilidad y la estabilidad.

- Utiliza un control modular para facilitar el mantenimiento y la resolución de problemas.

1.What type of PCB boards are suitable for your selective wave soldering machine?

A:Our selective wave soldering machine is especially suitable for high-density PCB boards with complex components (such as BGA, QFN, etc.), multi-layer, double-sided assembly. It can precisely control the soldering area to avoid waste and soldering errors.

2.Is your equipment maintenance and cleaning complicated?

A:Our equipment needs regular cleaning and maintenance, especially the crest part, to ensure its stability and long-term performance. With correct operation and regular maintenance, the service life of the equipment can be extended.

3.How is the soldering accuracy of your equipment?

A:Our selective wave soldering machine can provide high-precision soldering under the conditions of setting parameters on the PC side, especially when dealing with small components and high-density circuit boards, which can ensure the quality and consistency of solder joints.

4.How efficient are your equipment?

A:Our selective wave soldering machines are highly efficient and suitable for small batch and high mix production environments, but the soldering speed and efficiency will be affected by the complexity of the PCB board and the size of the soldering area.

5. How long is the warranty for your equipment? How is the after-sales service?

A: We provide a 1-2 year warranty (depending on the model) and lifetime technical support. Our after-sales service includes:

✅ Remote technical support (telephone/video guidance)

✅On-site maintenance (door-to-door service available)

✅Spare parts supply (equipment wearing parts can be provided for a long time).

Especificaciones destacadas

| Modelo | DEZ-H3630 |

|---|---|

| Dimensiones de la máquina | L1150mm X An1260mm X Al850mm (sin base) |

| Consumo total de energía | 5KW |

| Fuente de alimentación | Monofásico 220V 50HZ |

| Requisitos del cable de alimentación | Cable de cobre de 2,5 mm². |

| Requisitos de la fuente de aire | 3-5 kg/cm². |

| Requisito de fuente de nitrógeno | Requisito de pureza del nitrógeno: 99,999% |

| Sistema de control | PC industrial |

| Área de soldadura | 300X300MM |

| Método de colocación de PCB | Colocación manual |

| Ejes de movimiento | X, Y, Z |

| Control de movimiento | Servocontrol de bucle cerrado Panasonic |

| Precisión de posicionamiento | ± 0,05 mm |

| Tipo de bastidor | Soldadura del bastidor base de acero |

| Capacidad de flujo | 2L |

| Método de precalentamiento | Lámpara halógena |

| Potencia de precalentamiento | 5KW |

| Tiempo de fusión | 45 minutos (con precalentamiento programable) |

| Temperatura máxima del crisol de soldadura | 350 °C |

| Solder Pot Potencia | 1,2 KW |