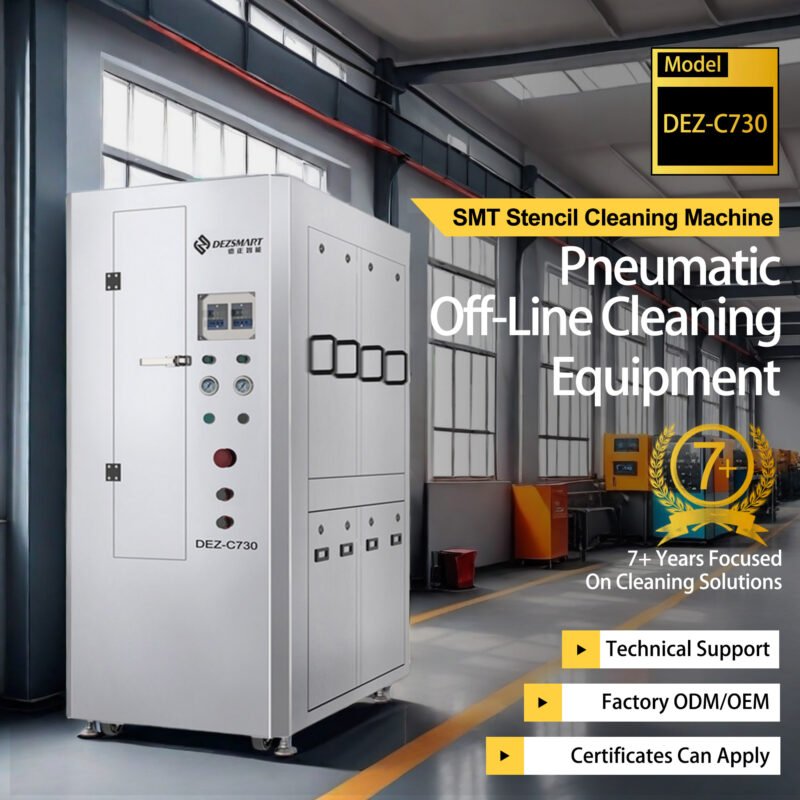

C730 Máquina neumática de limpieza de esténciles PCB

El C730 es un equipo neumático de limpieza automática de alto rendimiento que utiliza presión de aire para operar automáticamente desde la limpieza hasta el secado. Está diseñado para limpiar varios tipos de esténciles, como mallas de acero SMT, mallas de cobre, pantallas de seda, mallas microporosas y discos de oblea en la industria electrónica.

-

Limpieza de pantallas repetible y de alta calidad (incluye "paso fino");

-

Evita que el operario inhale sustancias nocivas;

-

Uso mínimo de disolventes;

-

Mejorar la eficiencia de la producción (esténcil limpio = serigrafía de alto nivel);

-

Mejorar el entorno de trabajo (limpieza automática frente a manual);

-

Funcionamiento neumático sin riesgo de incendio;

-

Llenado y vaciado automáticos de disolvente;

-

Bloqueo de seguridad de la puerta con indicador luminoso y botón de parada de emergencia (si la puerta no está bloqueada, la máquina no funcionará)

1. How is the cleaning effect of your equipment? Can it be thoroughly cleaned?

A:Of course! Our equipment uses high-pressure spraying + precision filtration technology, which can effectively remove solder paste, red glue and flux residues on the steel mesh to ensure the cleanliness of the steel mesh. At the same time, there is a drying function after cleaning to ensure that the steel mesh is dry and has no residue, and can be put into use immediately.

2. Will the steel mesh be damaged during cleaning?

A:Not at all! Our equipment uses a gentle but efficient cleaning method, which will not cause any damage to the steel mesh during the cleaning process, while avoiding the problems of mesh clogging or deformation that may be caused by traditional manual cleaning. Many customers have reported after use that the service life of the steel mesh has been significantly extended.

3. What kind of cleaning agents can be used in your cleaning machine? Is it environmentally friendly?

A:Our cleaning machine is compatible with solvent-based and water-based cleaning agents, ensuring the cleaning effect while meeting the industry’s environmental standards. Compared with traditional chemical cleaning methods, our equipment is safe and pollution-free.

4. Will the operation be complicated? Do I need professional training?

A:No! Our equipment is equipped with an intelligent touch screen operating system, which can be started with one button and automatically completes cleaning, rinsing and drying. It is simple and easy to learn, and ordinary employees can easily get started. If necessary, we can also provide detailed operation training to ensure that your team can use it smoothly.

5. Is it difficult to maintain the equipment? Is the later cost high?

A:Our equipment design is very user-friendly, simple to maintain and low cost. You only need to regularly replace the cleaning agent and check the filter system, and other parts are basically maintenance-free. We also provide comprehensive after-sales service and technical support to keep your equipment in the best working condition for a long time.

6. What stencils are suitable for your cleaning machine?

A:Our equipment is suitable for SMT steel mesh, copper mesh, silk screen, microporous mesh, and wafer discs of various sizes. If you are not sure whether it is suitable for your stencil, you can contact us and we will recommend the most suitable model according to your needs.

7.Can your stencil cleaning machine improve production efficiency?

A:Of course! It usually takes 3-10 minutes to clean a stencil, which is much faster and more effective than traditional manual cleaning. It also has a stable cleaning effect. It reduces printing defects caused by unclean stencils, improves production yield, and ultimately helps you reduce costs and increase production capacity.

Especificaciones destacadas

| Modelo de dispositivo | C730 |

|---|---|

| Nombre del dispositivo | Máquina neumática de limpieza de esténciles C730 |

| Tamaño del panel aplicable | Máximo 750 mm (largo) × 750 mm (ancho) × 40 mm (alto) |

| Tamaños personalizados disponibles bajo pedido | |

| Capacidad del líquido limpiador | 40L (Máximo) |

| Uso óptimo del líquido | 30L |

| Método de limpieza | Chorro de igual presión por ambos lados con rotación de 360°, chorro de alta presión (limpieza → secado). |

| Tiempo de limpieza | 2-8 minutos (proceso estándar) |

| Tiempo de secado | 2-8 minutos (proceso estándar) |

| Suministro de aire externo | 0,5MPa ~ 0,65MPa |

| Método de filtración | Filtración en tres etapas |

| Filtración de 1ª etapa | 10μm (elimina restos y etiquetas) |

| Filtración de 2ª etapa | 5μm (elimina impurezas de tinta, pasta de plata) |

| Filtración de 3ª etapa | 1μm (elimina partículas diminutas) |

| Tamaño del orificio de escape | Φ125(ancho) × 25mm(alto) |

| Peso neto | Aproximadamente 200 kg |

| Dimensiones de la máquina | 1000 mm (largo) × 710 mm (ancho) × 1720 mm (alto) |

| Aire comprimido | 600-900L/Min |