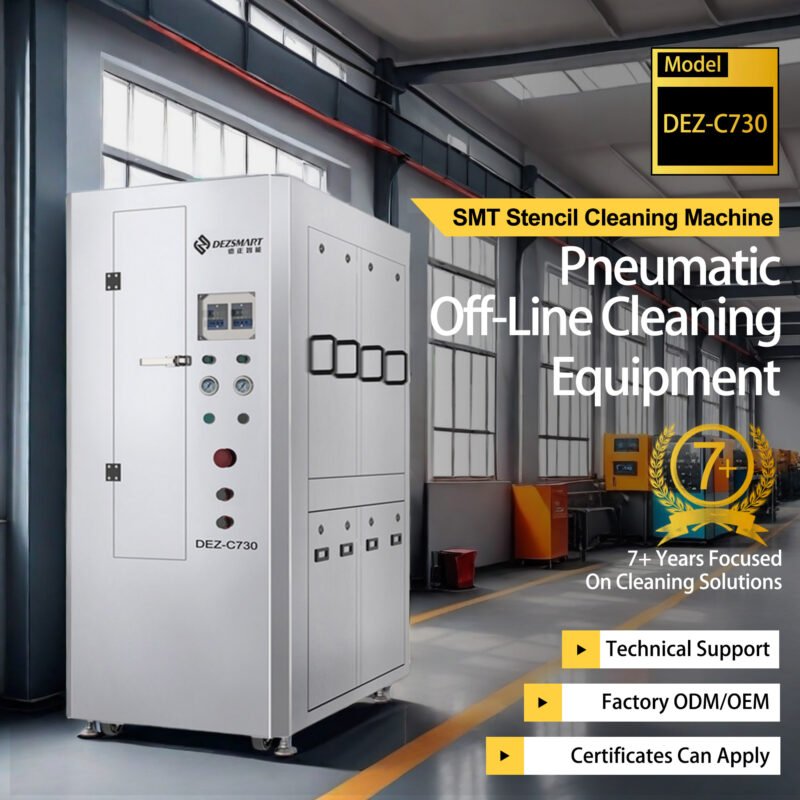

C730 Pneumatische PCB-Schablonenreinigungsmaschine

Die C730 ist eine leistungsstarke pneumatische automatische Reinigungsanlage, die mit Hilfe von Luftdruck automatisch von der Reinigung bis zur Trocknung arbeitet. Sie ist für die Reinigung verschiedener Arten von Schablonen wie SMT-Stahlgewebe, Kupfergewebe, Siebdruck, mikroporöses Gewebe und Waferscheiben in der Elektronikindustrie konzipiert.

-

Hochwertige, wiederholbare Schablonenreinigung (einschließlich "fine pitch");

-

Verhindert das Einatmen von Schadstoffen durch den Bediener;.

-

Minimaler Lösungsmittelverbrauch;

-

Verbesserung der Effizienz der Produktion (saubere Schablone = hoher Siebdruck);

-

Verbesserung der Arbeitsumgebung (automatische Reinigung vs. manuelle Reinigung);

-

Pneumatischer Betrieb ohne Brandgefahr;

-

Automatisches Befüllen und Ablassen von Lösungsmitteln;

-

Sicherheitstürverriegelung mit Leuchtanzeige und Not-Aus-Taste (wenn die Tür nicht verriegelt ist, funktioniert die Maschine nicht)

1. How is the cleaning effect of your equipment? Can it be thoroughly cleaned?

A:Of course! Our equipment uses high-pressure spraying + precision filtration technology, which can effectively remove solder paste, red glue and flux residues on the steel mesh to ensure the cleanliness of the steel mesh. At the same time, there is a drying function after cleaning to ensure that the steel mesh is dry and has no residue, and can be put into use immediately.

2. Will the steel mesh be damaged during cleaning?

A:Not at all! Our equipment uses a gentle but efficient cleaning method, which will not cause any damage to the steel mesh during the cleaning process, while avoiding the problems of mesh clogging or deformation that may be caused by traditional manual cleaning. Many customers have reported after use that the service life of the steel mesh has been significantly extended.

3. What kind of cleaning agents can be used in your cleaning machine? Is it environmentally friendly?

A:Our cleaning machine is compatible with solvent-based and water-based cleaning agents, ensuring the cleaning effect while meeting the industry’s environmental standards. Compared with traditional chemical cleaning methods, our equipment is safe and pollution-free.

4. Will the operation be complicated? Do I need professional training?

A:No! Our equipment is equipped with an intelligent touch screen operating system, which can be started with one button and automatically completes cleaning, rinsing and drying. It is simple and easy to learn, and ordinary employees can easily get started. If necessary, we can also provide detailed operation training to ensure that your team can use it smoothly.

5. Is it difficult to maintain the equipment? Is the later cost high?

A:Our equipment design is very user-friendly, simple to maintain and low cost. You only need to regularly replace the cleaning agent and check the filter system, and other parts are basically maintenance-free. We also provide comprehensive after-sales service and technical support to keep your equipment in the best working condition for a long time.

6. What stencils are suitable for your cleaning machine?

A:Our equipment is suitable for SMT steel mesh, copper mesh, silk screen, microporous mesh, and wafer discs of various sizes. If you are not sure whether it is suitable for your stencil, you can contact us and we will recommend the most suitable model according to your needs.

7.Can your stencil cleaning machine improve production efficiency?

A:Of course! It usually takes 3-10 minutes to clean a stencil, which is much faster and more effective than traditional manual cleaning. It also has a stable cleaning effect. It reduces printing defects caused by unclean stencils, improves production yield, and ultimately helps you reduce costs and increase production capacity.

Ausgewählte Specs

| Gerätemodell | C730 |

|---|---|

| Gerät Name | C730 Pneumatische Schablonenreinigungsmaschine |

| Anwendbare Panelgröße | Maximal 750mm(L) × 750mm(B) × 40mm(H) |

| Kundenspezifische Größen auf Anfrage erhältlich | |

| Kapazität der Reinigungsflüssigkeit | 40L (Maximum) |

| Optimale Verwendung von Flüssigkeiten | 30L |

| Reinigungsmethode | 360° rotierende zweiseitige Gleichdruckdüsen, Hochdruckdüsen (Reinigung → Trocknung) |

| Reinigung Zeit | 2-8 Minuten (Standardverfahren) |

| Trocknungszeit | 2-8 Minuten (Standardverfahren) |

| Externe Luftzufuhr | 0,5MPa ~ 0,65MPa |

| Filtrationsverfahren | Dreistufige Filtration |

| 1. Stufe der Filtration | 10μm (entfernt Ablagerungen und Etiketten) |

| 2. Stufe der Filtration | 5μm (entfernt Tintenverunreinigungen, Silberpaste) |

| 3. Stufe der Filtration | 1μm (entfernt winzige Partikel) |

| Größe der Auslassöffnung | Φ125(B) × 25mm(H) |

| Nettogewicht | Ungefähr 200kg |

| Abmessungen der Maschine | 1000mm(L) × 710mm(B) × 1720mm(H) |

| Pressluft | 600-900L/Min |