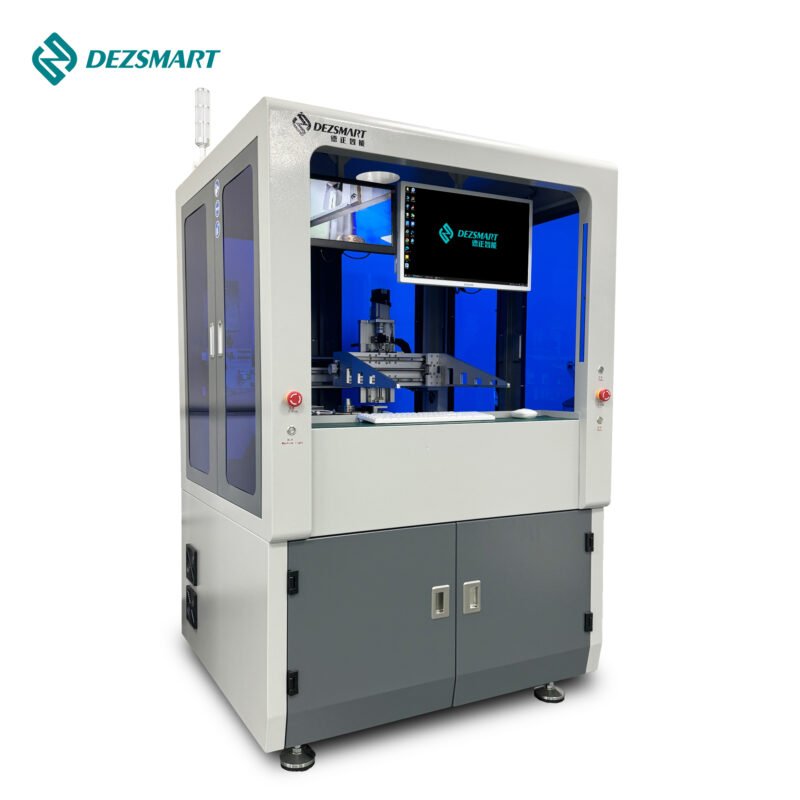

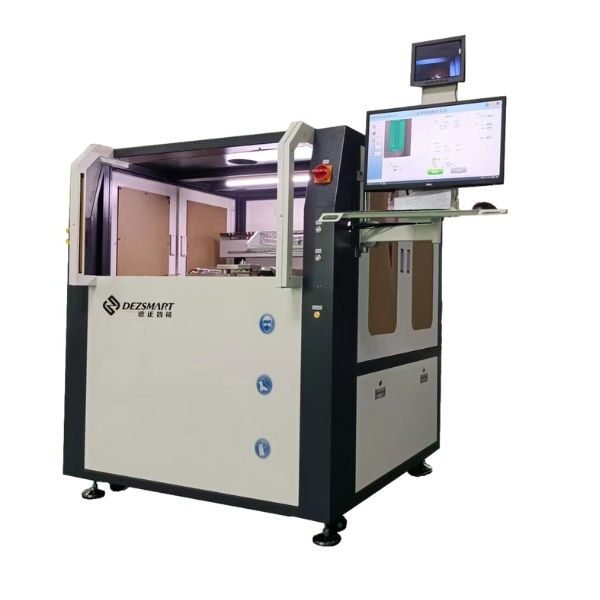

H3500A Selective Wave Soldering Machine

H3500A Three-axis linkage selective wave soldering machine, the machine software system is developed based on WINDOWS10, the PCB picture can be directly used for path programming, and various data parameters can be set on the computer and monitored by the software. The equipment has a high level of automation and is suitable for complex board-level soldering.

- Fully functional offline model with compact footprint.

- High quality soldering.

- Can used beside production line, flexible for production line forming.

- Fully computer controlled, all parameters are set and saved on the computer. Generate configuration files for easy traceability and storage.

- The PCB image can be used directly for path programming. The path starting point, welding moving speed, idle stroke speed, Z-axis height, wave peak height, etc. can all be set on the computer.

- The whole machine is made of steel structure, with a base plate at the bottom to increase the stability of the machine and reduce vibration

1.What type of PCB boards are suitable for your selective wave soldering machine?

A:Our selective wave soldering machine is especially suitable for high-density PCB boards with complex components (such as BGA, QFN, etc.), multi-layer, double-sided assembly. It can precisely control the soldering area to avoid waste and soldering errors.

2.Is your equipment maintenance and cleaning complicated?

A:Our equipment needs regular cleaning and maintenance, especially the crest part, to ensure its stability and long-term performance. With correct operation and regular maintenance, the service life of the equipment can be extended.

3.What packaging types are suitable for your selective wave soldering machine?

A:Suitable for most SMT components, especially BGA, QFN, CSP and other difficult-to-solder packaging types. For some special packages, parameter adjustment may be required according to actual conditions.

4.How is the soldering accuracy of your equipment?

A:Our selective wave soldering machine can provide high-precision soldering under the conditions of setting parameters on the PC side, especially when dealing with small components and high-density circuit boards, which can ensure the quality and consistency of solder joints.

5.How efficient are your equipment?

A:Our selective wave soldering machines are highly efficient and suitable for small batch and high mix production environments, but the soldering speed and efficiency will be affected by the complexity of the PCB board and the size of the soldering area.

Featured Specs

| Machine name | DEZ-H3500A | Flux management | ||

|---|---|---|---|---|

| dimension | L1000mm X W1133mm X H1810mm | flux nozzle | Injection valve | |

| general power | 3kw | flux tank capacity | 1L | |

| consumption power | 1kw | flux tank | Flux box | |

| power supply | 220V 50HZ | Solder pot | ||

| net weight | 380KG | standard pot number | 1 | |

| reuiqred air source | 3-5 Bars | solder pot capacity | 10~15 kgs/furnace | |

| required air flow | 8-12L/min | Temperature range | PID | |

| required N2 pressure | 3-4 Bars | melting time | 30--40 Minutes | |

| required N2 flow | More than 2 cubic meters per hour | max temperature | 350 C | |

| N2 purity | 》99.998% | solder heater | 1.2kw | |

| carrier | Can be used as needed | Soldering nozzle | ||

| max solder area | L320 X W410mm (Customizable size) | nozzle dim | Customizable shapes | |

| PCB thickness | 0.2mm-----6mm | material | Alloy steel | |

| pcb edge | 3mm or more | Equipped nozzle | Standard 5 pieces/furnace | |

| controlling | Industrial PC | N2 management | ||

| Loading board | Manual | N2 heater | Standard | |

| Unloading board | Manual | N2 temp range | 0 - 350 C | |

| Operating height | 900+/-30mm | N2 consumption | 1---2m3/hour/tin nozzle | |

| conveyor up clearance | Unlimited | |||

| conveyor bottom clearance | 30MM | |||

| motion axis | X, Y, Z | |||

| motion control | Step | |||

| position accuracy | + / - 0.1 mm | |||

| chassis | Steel welding |